CASE STUDIES

HPHT HYDROCARBON PROCESS OBSERVATION

CUSTOMER CHALLENGE:

A university workgroup required a large aperture ASME flange equipped window for analysis prior to project commercialization. In addition, Canada has some of the most stringent pressure vessel regulations in the world and approval for a CRN (Canadian Registration #) is awarded after technical submissions are reviewed a provincial reviewing body. This unique challenge presented a complex mix of regulatory and engineering hurdles needed to satisfy a demanding petrochemical application.

RAYOTEK SOLUTION:

The knowledge of specialty glass to metal sealing was the key component of this successful project delivery. A modified, ASME B31.2 compliant Rayotek flange configuration sealed to a custom designed window allowed for the combination of large clear aperture, high temperature and high pressure (relative to aperture size) to meet client requirements.

FINISHED PRODUCT:

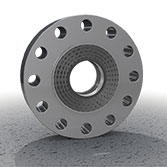

HPHT Process Observation Flange Window ~ Specifications Achieved:

- Interface - ASME 6” flange (900# modified)

- Housing Material - 316 stainless

- Window Material - Optical grade fused quartz (4.25” clear aperture)

- Mounting - Redundant gasket seal assembly

- Operating Pressure - 0 to 1100 psi (cycling)

- Operating Temperature - 5ºC to 510ºC

- Environmental Exposure - Hydrocarbon emulsion (proprietary)

- Additional Notes - CRN registration required a 10x pressure validation pressure test and subsequent calculations to certify window material.