HIGH TEMPERATURE SIGHT GLASS WINDOWS - HIGH & LOW PRESSURE

HIGH PRESSURE, HIGH TEMPERATURE (HPHT) SIGHT GLASS WINDOW SYSTEMS

Industries such as research, aerospace, refining, industrial manufacturing and materials technologies are experiencing technological advancements at a rapid rate. A significant contributor to these changes is improvement and refining of support technologies for observing and measuring.

Direct observation of hazardous?? dangerous reactions is best performed through the use of High Pressure, High Temperature (HPHT) Sight Glass Windows. A properly designed, built and utilized HPHT Sight Window is virtually indestructible in the most hostile environments, protects personnel and allows for the successful study and risk reduction of dangerous applications.

Rayotek HPHT Sight Glass Window allow for transmission of signals from as low as 130nm to over 20microns, including microwave and radio wave signals. This wide spectrum transmission capability supports particle size, shape and count studies, spectroscopy, in-situ metrology, pyrometry and high-speed videography in the UV, visible and IR spectrums.

Rayotek’s extensive line of build to order and custom High Pressure, High Temperature Sight Glass Windows (HTHP) provide clients with improved functionality, portal size, insulating performance, operating limits and overall quality. With the world’s largest custom engineered Sight Window database and an in-house team of engineers and glass specialists, Rayotek is the go-to source for tailored HPHT Sight Window solutions.

High Temperature, High Pressure Sight Glass Window Capabilities:

For direct observation and measurement of internal processes at temperatures up to:

Design Specifications

Pressure Ratings |

Highest in the industry (custom applications up to 65 KPSI) |

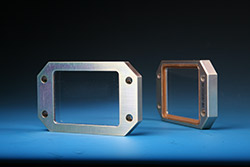

Window Shape/Interfaces |

Round & square clear aperture, a variety of threaded & flanged options, plus custom connection designs |

Window Material |

Fused quartz, fused silica, borosilicate, sapphire & exotics for deep IR |

Housing Configurations |

Straight, angular mount, periscope, blast gate, peep sight |

Housing Material |

Carbon steel, stainless steel, Inconel, Duplex, ceramic NACE compliant & super alloy metals |

Coatings |

Heat reflecting, wavelength specific AR |

Applications For Hpht Sight Windows Cover A Brought Spectrum Of Industries Including:

- Oil & Gas

- Renewable Energy Systems

- Chemical Processing

- Hydraulics

- Combustion Technology

- Rocket Science (yes, even rocket science)

HIGH TEMPERATURE (LOW/AMBIENT PRESSURE) WINDOWS – FURNACE & INCINERATOR

Companies involved in manufacturing, industrial and research processes requiring observation or measurement portals are often limited to products designed and engineered over half a century ago. Legacy Sight Glass Windows are often purchased with no knowledge of improvements to technology and product offerings. To further complicate the situation, OEM replacements are often non-existent, leaving engineers and maintenance teams with limited alternatives.Rayotek’s in-house engineering team provides custom solutions and OEM replacements for clients looking to improve their systems with the addition of first mover technologies such as our Vacuum Insulated Sight Glass Windows and abrasion resistant, optical enhancement and notch filter coatings. These windows provide the maximum amount of insulating value possible in order to allow observations and pyrometry for increased periods of time without substantial heat loss.

High Temperature, Low Pressure Sight Glass Window Systems offer the ideal blend of economy, functionality and serviceability. They allow direct observation of processes involving high temperature such as heat treating, coating or other low/ambient pressure operations with no need for process disruption. This increases efficiency, reduces energy variations and can allow for more accurate data gathering during course of the heating/cooling process.

Applications For Furnace & Incinerator Sight Windows:

- Blast Furnace

- Kiln

- Lime Kiln

- Induction furnace

- Smelting operations